Small-Batch Custom Builds

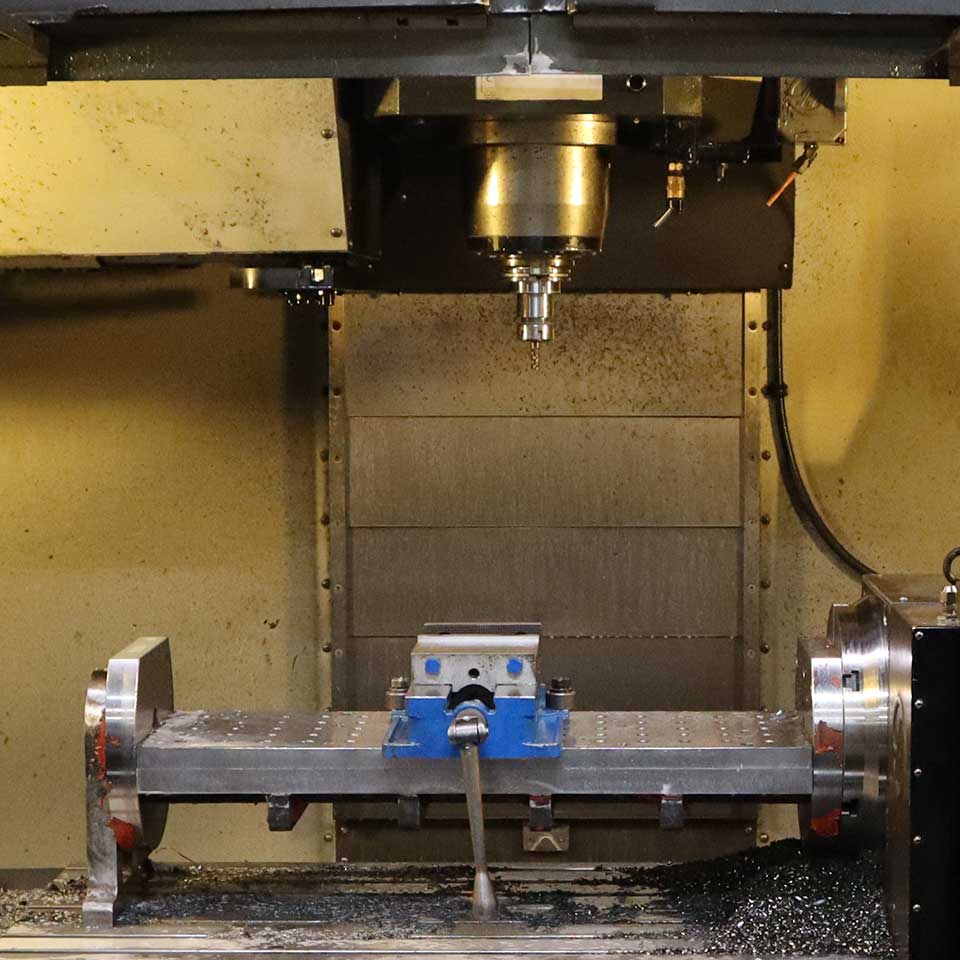

Keep the heaviest builds working like clockwork, with stable sub bases, motor mounts, pedestals, and frames. Our Metal Fabrication Shop produces precision-built structures in a variety of metals, weighing up to 10,000 lbs. Parts from the Fabrication Shop are finished in our Computer Numerical Control (CNC) Machine Shop, assembled, and load tested for seamless performance — all in-house for efficiency and quality control.

Let's Talk About Your Project