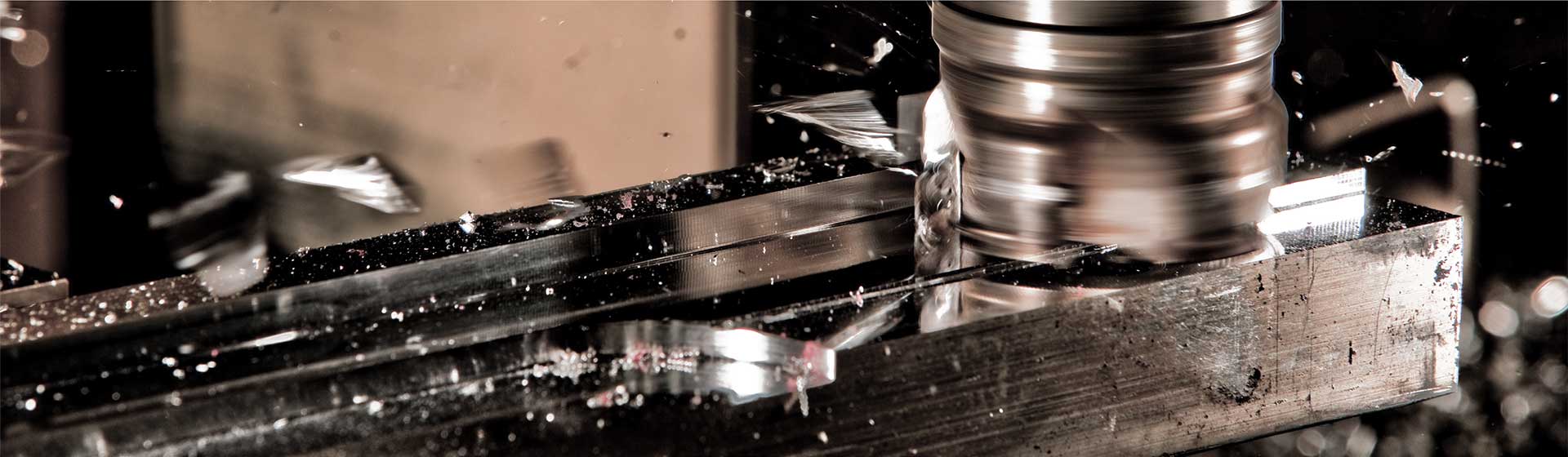

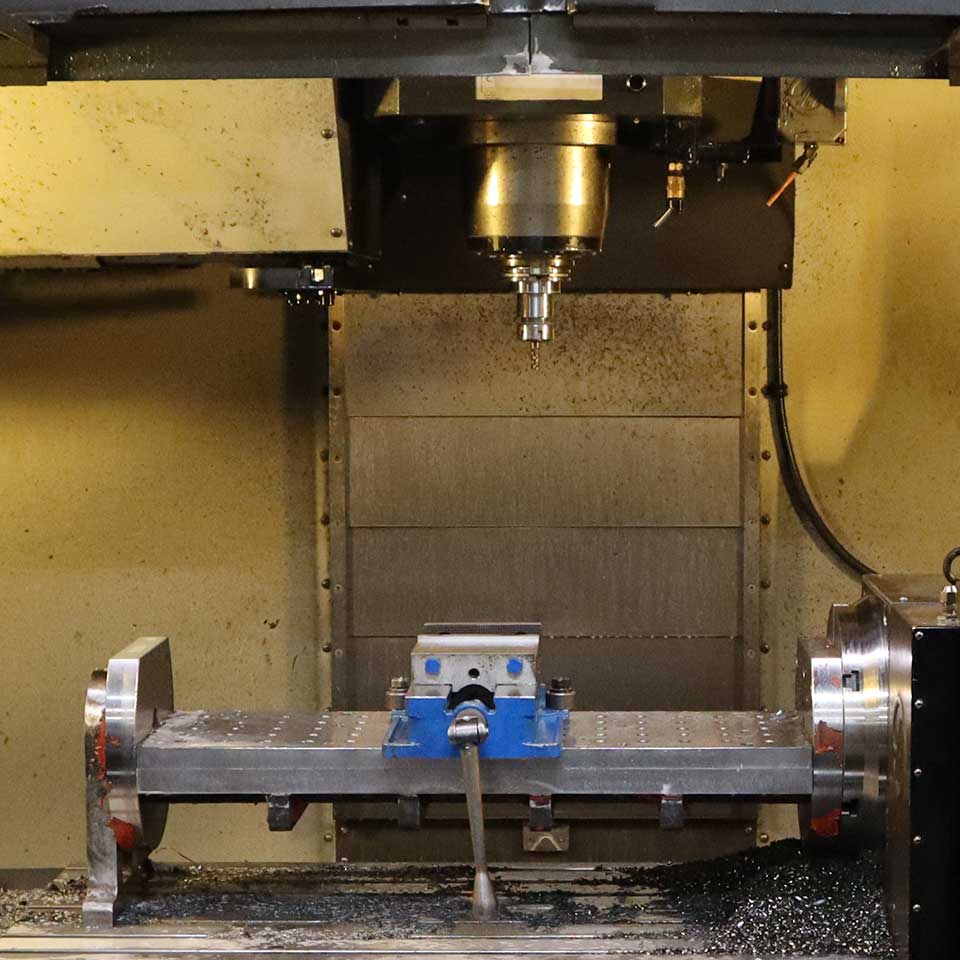

Precision Machining and Quality Assurance

Reduce lead times by finishing parts right where they’re made! The West Point CNC Machine Shop uses Computer Numerical Control (CNC) machining to produce finished components—with one source of responsibility. Our team’s highly skilled workmanship and in-house quality testing ensure a clean finish and tight tolerances every time, for performance you can count on.

Let's Talk About Your Project